TOPIC:

Home Vac Former For making RC car bodies 7 years 1 day ago #43255

|

Wow what a project!

I learn something new every time I come here, thanks for posting all this for the rest of us too see!! From somewhere out in the wilds of central Ontario.

.......you build what you like, I will build what I like........it's all cool...... |

|

|

Please Log in to join the conversation. |

Home Vac Former For making RC car bodies 6 years 11 months ago #43288

|

thanks everyone.

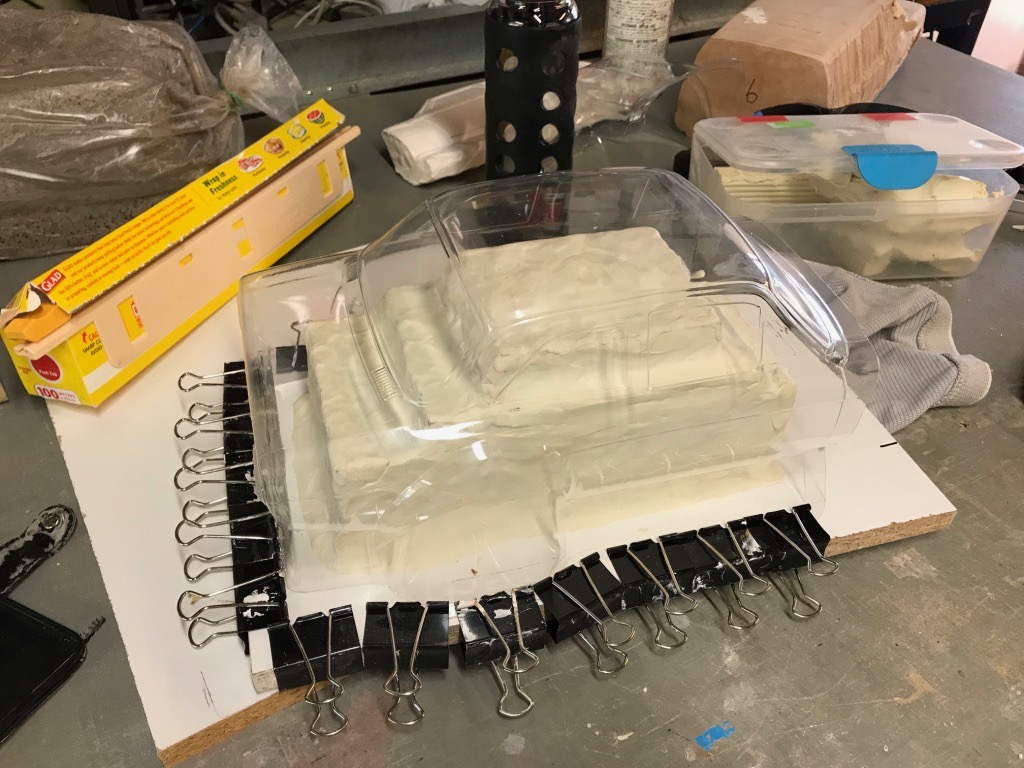

I thought I'd do one more post on how I am current making my molds. In my first version of the vac former I drilled hundreds of holes into the platten. This helps suck down the entire sheet of plastic. Since then I've ended up changing to a single hole in the middle. Drilling all those holes is really tedious! I also changed it because of the way I wanted to shape the plastic. The car bodies I am making have lots of detail and to get the detail you need to be able to make little channels that draw air out from that area. Although I wonder if this way increases the webbing I am getting at the corners. My method of making the molds is with a cavity underneath, which not only saves a lot in plaster, but can help in directing how the air escapes. I start off with a board cut to the size I need and then build up sheets of MDF that are lightly glued together. I then cover that in plasticine, as this makes removal a lot easier later on. Fit the body to be copied over the top, making sure its completely sealed around the edges. I also add some extra tape around the top so I can over fill it a little. In case leaks occur, I stand it up in a small tray. Once the plaster sets, I turn upside down and remove the cavity inserts. It takes several hours for the plaster to dry really hard, so after is firm but not completely dry, I then go over all the panel lines and score them a bit deeper. I this as I was finding a lot of this detail was being lost when vac forming with thicker material. I then drill pinholes where there is extra details. I try and use a 0.8 mm diameter drill bit.

The following user(s) Liked this: stingray-63

|

|

|

Please Log in to join the conversation. |

Home Vac Former For making RC car bodies 6 years 11 months ago #43289

|

Beautifull!

|

|

Please Log in to join the conversation. |

Home Vac Former For making RC car bodies 6 years 11 months ago #43311

|

Thank you for sharing, Yogi!

It's really interesting reading! Signature now gets correct formatting if you edit it in your Profile. Use normal BBcode if you want.

www.tamiyabase.com was formatted automatically. |

|

|

Please Log in to join the conversation. |

Home Vac Former For making RC car bodies 3 years 10 months ago #60035

|

Such a great thread. Thank you for sharing all your leaps and bounds!

|

|

Please Log in to join the conversation. |

Home Vac Former For making RC car bodies 3 years 10 months ago #60040

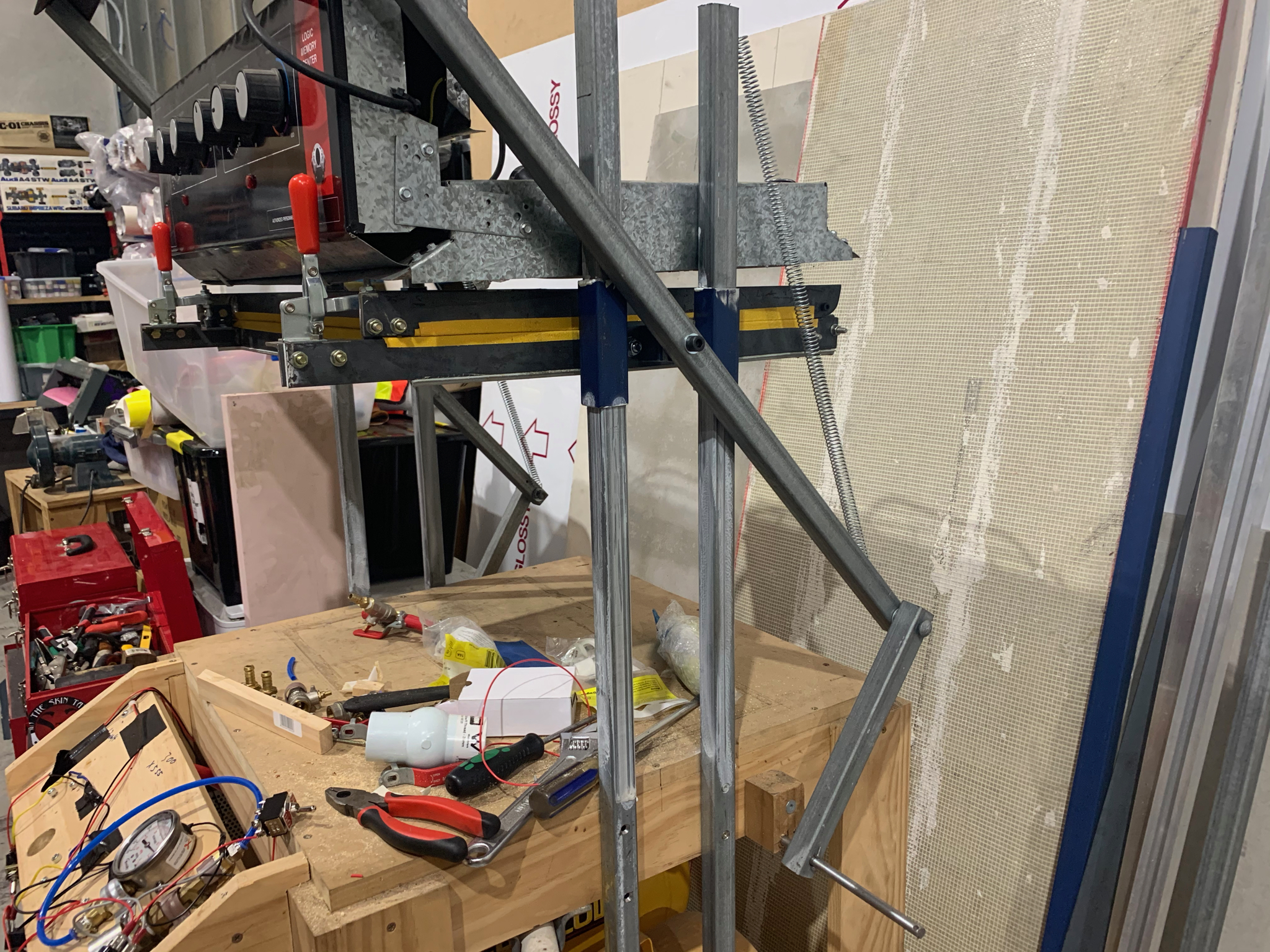

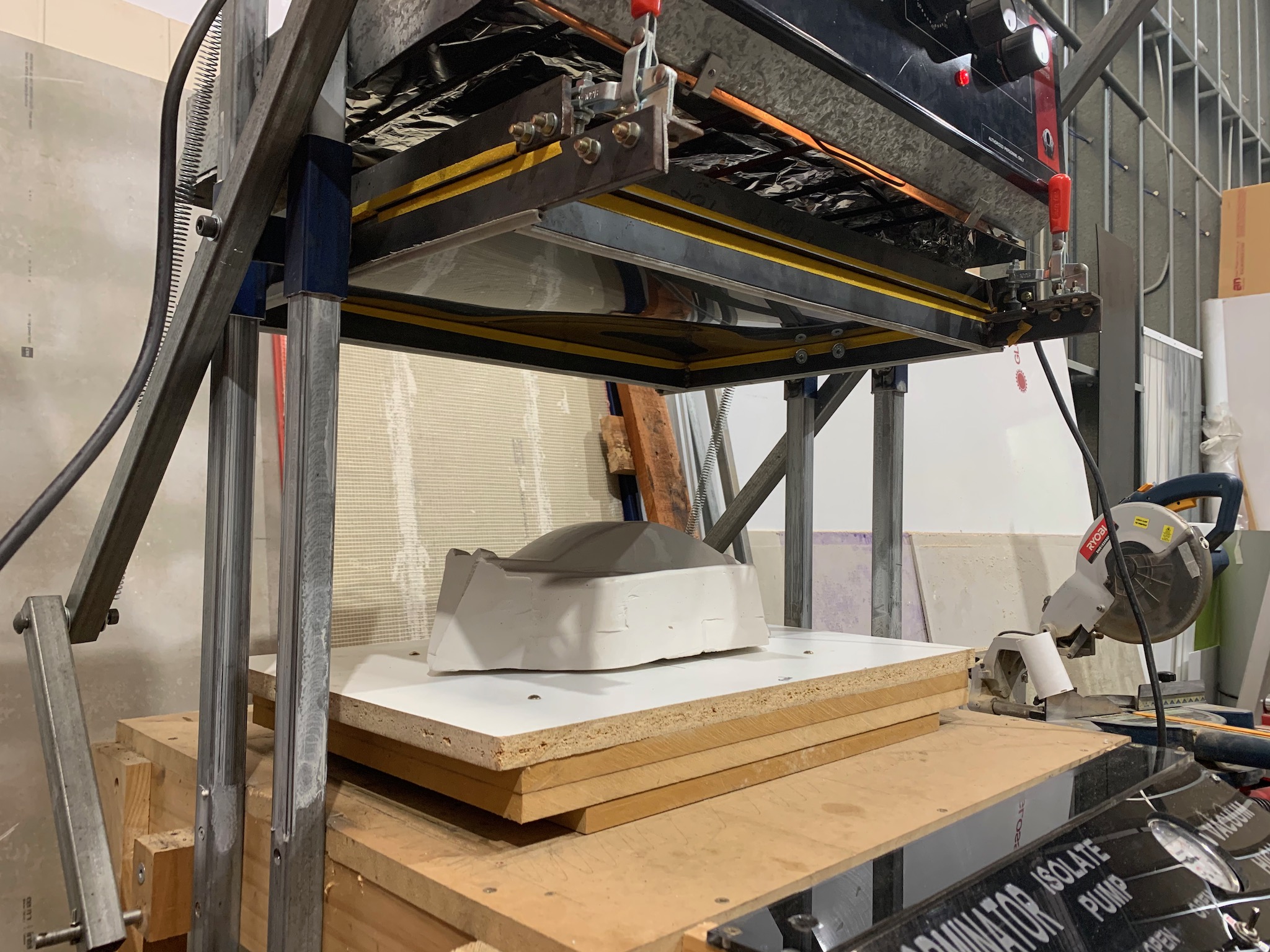

Thanks, which reminds me, this year I did some more upgrades to the hinge and where it means the frame. Previously it was wood, now have made it all out of metal and its a lot more right. I also raised the platform so it is higher than the centre of the frame where the plastic meets. This resulted in a much improved sealing when pulling down the plastic. The photo shows High Impact Styrene being formed, but it should be the same as ABS, which I'm hoping to try today.

The following user(s) Liked this: stingray-63

|

|

|

Please Log in to join the conversation. |

Home Vac Former For making RC car bodies 3 years 10 months ago #60043

|

Nice yogi!

The following user(s) Liked this: yogi-bear

|

|

Please Log in to join the conversation. |

Home Vac Former For making RC car bodies 3 years 10 months ago #60046

|

I see an old ColorCAMM plotter in the background. Great machines. Terrible print head life.

The following user(s) Liked this: yogi-bear

|

|

Please Log in to join the conversation. |

Home Vac Former For making RC car bodies 3 years 10 months ago #60048

keen eyes! Not quite though, it is just a Roland Camm-24 that I've had for about 20 years, it only cuts, no printing. It still works well too, but I only have XP drivers for it. |

|

|

Please Log in to join the conversation. |

Home Vac Former For making RC car bodies 3 years 10 months ago #60588

|

Thanks For sharing your progress Yogi! Impresive results

I'm trying myself to vac my own bodies and not close to your level of detail yet... Not to mention that my "gear" is very domestic... but still, having fun trying to achieve an acceptable result from my 3D printed mold. These days is hard to source plastic sheets due to Covid, so I'm testing with any sheet I can find. So far, my tests failed with 1mm lexan and succeded with 0.5 PETG and 0.7 PVC. Reading from your experience, the problem with lexan is it gets cold so fast, so I don't even get to pull the sheet all the way down over the body... at half way it just won't deform more so I can't really vac. Want to try with 0.5 or 0.75 lexan but haven't sourced any sheet yet. PETG is way easier to deform and with 0.5 the level of detail is great. But too thick, so want to try with 0.75 and 1mm PETG. At last, I found a sheet of 0.7 PVC that is giving me good results. Ever tried that? I really don't know the specs of this plastic, so I don't know how bad it can be for a RC body (breakable? no UV?). But it's way cheaper that lexan! I'll try to post my results later |

|

|

Please Log in to join the conversation. |

Time to create page: 0.212 seconds