TOPIC:

Re: Hop-up motors possible 11 years 5 months ago #17138

|

LOGIC!!! |

|

Please Log in to join the conversation. |

Re: Hop-up motors possible 11 years 5 months ago #17159

|

Yep, I agree with all of that, but will add -

The sintered bronze bearings are porous (Full of minute air holes, like a sponge) & trap the oil within them. As far as I know, it's the heating up of the bearing in use that makes it expand & force the oil out into the (Supposedly) close-tolerance gap, behaving like it was pressurised from a pump. But yes, it's the same oil that gets used over & over & it will become contaminated over time & cause wear. If the gap is too big (eg through wear or poor tolerancing) the oil will escape & you get metal-on-metal contact & again, wear. If the tolerances are right, the spindle should never come in contact with the bush metal, there should be a thin layer of oil between the parts. The molecules of oil act like the balls in your ballraces. The trouble comes when the oil can be squeezed out of the gap. To recharge sintered bronze bushes, you have to warm them up in a bath of oil, then let them cool. The contraction of the cooling metal "sucks" the oil into the pores & keeps it there (Again, like a sponge). Getting crap in bronze bearings also applies to ballraces. Bronze bearings should trap it within their pores, but ballraces will grind it up to form an aggressive grinding paste. The way around that is to use rubber sealed ones, but that would introduce friction & you're back to square one. Other option is to keep the ballraces scrupulously clean, or keep replacing them when they get dirty. Really not sure about this one... I think good/new ballraces on a good/new spindle would be beneficial for reducing friction, that's common sense, BUT because they're not the right equipment for the application, their useful life is much reduced. HOWEVER, how long do they really need to last, 3 or 4 races? I suppose the way to look at it is, it's a similar scenario to motoX or dragster engines - they only have to improve the performance long enough to win races, & are rebuilt using new parts every few races to keep them in tip-top condition. There's no way one of these engines would survive driving 4 miles to work & back every day for a week! Yep, I've already tried replacing bronze motor bearings with ballraces & compared performance, it always makes them noisy & slower. BUT as I said before, this has only been on the bench, I've never got as far as plonking one in a car & driving it to see what it's like. AND the bearing replacements have been on previously used motors, so the issue could be poor fit due to spindle wear. Something else to remember is that toy car motors are mass produced & to keep cost down they probably aren't very highly toleranced. The spherical rear bush to aid alignment in some is a clue, as is the need to make the comm properly round before you can race it is another. I've often toyed with the idea of scratch-building a high tolerance motor, just to see what it would be like, but it's one of those things that doesn't matter for bashing, so I just haven't got around to it!

Custom F2

...

Hilux crossmember drawing

...

F2 axle drawing

...

Quattro radio lid

...

Holiday Buggy motor bracket drawing

...

Quattro resto

...

HitnMiss engine

...

Wild Willy resto

...

Mardave Cobra resto

...

Thunder Dragon resto

...

Grasshopper resto

...

XR311 resto

...

Modded XR311

...

Carbon 25th scratch build

|

|

|

Please Log in to join the conversation. |

Re: Hop-up motors possible 11 years 5 months ago #17167

|

I am now back in town...

Boy - talk about waxing lyrical - I thought I had asked a simple question Seriously - I am please it generated some interesting discussion... I will have to think about how much I want to spend on this. WIll let you now what I decide to do |

|

|

Please Log in to join the conversation. |

Re: Hop-up motors possible 11 years 5 months ago #17170

|

Sorry, got distracted by an interesting subject!

If you wanna go quicker with minimal outlay, I suggest looking at any of the "Epic" canned brushed motors. They come with a variety of different manufacturer's labels on them, but the way to spot them is the flatted sides & venting in the can, "Epic" stamped on the front, lay-down brushes & lightened rotor. "Revenge of the monster horsepower" is a good example - 27T but relatively mental performance fairly cheaply. You do have to watch the turns rating on ESCs with them though as they pull a lot more current than the ESC manufacturer anticipates for a given number of turns. At the end of the day, it depends on what you plan to do with the car & how much money you're comfortable spending to achieve your goal. For me, some tuning for increased bashing hilarity usually comes for less than a tenner in the form of a 2nd hand Epic & an hours tinkering to fix it

Custom F2

...

Hilux crossmember drawing

...

F2 axle drawing

...

Quattro radio lid

...

Holiday Buggy motor bracket drawing

...

Quattro resto

...

HitnMiss engine

...

Wild Willy resto

...

Mardave Cobra resto

...

Thunder Dragon resto

...

Grasshopper resto

...

XR311 resto

...

Modded XR311

...

Carbon 25th scratch build

|

|

|

Please Log in to join the conversation. |

Re: Hop-up motors possible 11 years 5 months ago #17218

|

Interesting indeed - I'm on the lookout for an ESC that will run on 4 cells.

I'm sure it will only be a matter of time before they become more widely available, if they're any good. Same story with the ratings though, the 240A will be the failure rating of the FETs, not the current handling capability. I've got some 90A rated diodes here somewhere (Bought for a welder project), I should really dig them out & post a pic of what proper high current rated components look like!

Custom F2

...

Hilux crossmember drawing

...

F2 axle drawing

...

Quattro radio lid

...

Holiday Buggy motor bracket drawing

...

Quattro resto

...

HitnMiss engine

...

Wild Willy resto

...

Mardave Cobra resto

...

Thunder Dragon resto

...

Grasshopper resto

...

XR311 resto

...

Modded XR311

...

Carbon 25th scratch build

|

|

|

Please Log in to join the conversation. |

Re: Hop-up motors possible 11 years 5 months ago #17222

|

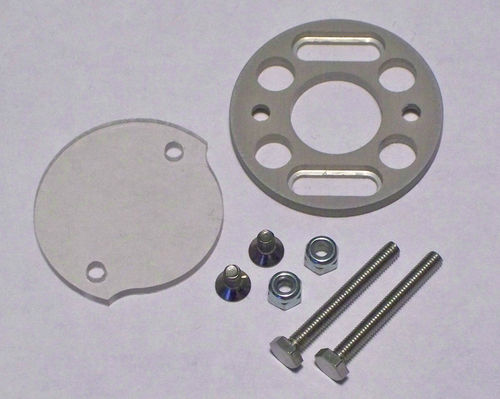

Right, a couple of pics then...

First pic is a selection of motors. Far left is a (Very poorly) Epic rotor, to show the lightened armature. (This is what happens when you stick 7A through a stalled motor). The 3x slotted cans are "Epic" type ones, note the distinctive shape(s) In case you were wondering, I painted the 2x purple, 1x has a 21T Annsmann Clash rotor in it (A sole survivor, I won't be using it), the other is a hand wound 50T I built for experimental purposes. Top are 2x Yokomo canned modifieds, both ballraced. Can't remember what the Reedy is, but it's mental quick on the bench & dog slow in my TL01 (It's probably designed for a 1/12 pan car). The one with the "Bullet" label on it is another I hand wound, 17x1 with 0.9mm dia wire, this goes like stink in the TL, but I had to retire it as the ballraces have worn out & gone "gritty" (Suspect overspeeding, as it hasn't been anywhere near dirt/dust). Next pic is to illustrate a raised eyebrow over ESC ratings. Top is an LRP ESC rated 180A Left is a diode rated 90A, then 2x 65A rated FETs (Manufacturer's blurb says they have to be mounted on a huge heatsink to withstand rated current). The smaller FET is 5A rated, this package size can be used up to 10A with a BIG heatsink. This is the package size most good brushed ESCs use, & are usually "stacked" to share the current. At the far right, is a FET from a Tazer 12T ESC. Note it has 6x pins, this is because there are 2x "stacked" FETs in the package. Note also that these are what's used in the Kyosho Mini-Z 1/28 cars, designed for use with 4x AAA cells, so quite why we would expect them to be ok with a 12T 540... Note the wiring on the LRP ESC. It's 2.5mm CSA, which from memory is rated 41A maximum, again an eyebrow raiser if they're expecting their ESC to be able to pass 180A. Although I'm not going to try it (Mainly as I don't have any spare ESCs), I suspect pumping 180A through that ESC is likely to vapourise it, 70A is more than enough to pop a hole in 3mm thick steel plate, & electronic components tend to be a lot less resilient

Custom F2

...

Hilux crossmember drawing

...

F2 axle drawing

...

Quattro radio lid

...

Holiday Buggy motor bracket drawing

...

Quattro resto

...

HitnMiss engine

...

Wild Willy resto

...

Mardave Cobra resto

...

Thunder Dragon resto

...

Grasshopper resto

...

XR311 resto

...

Modded XR311

...

Carbon 25th scratch build

|

|

|

Please Log in to join the conversation. |

Re: Hop-up motors possible 11 years 5 months ago #17263

|

Someone know the team kinwald green machine? I have one on my XPRESS. and homit what type of motor it is. |

|

Please Log in to join the conversation. |

Re: Hop-up motors possible 11 years 5 months ago #17291

I had serious motor temperature problems and battery runtime limitations when I tried a slightly faster motor (Carson Cup Machine) in the Mad Bull. This was due to the large diameter monster truck wheels and stock DT-01 gearing - both do not like to be combined with each other. But eventually, I found a way how to let the Mad Bull go faster. The first thing was an aftermarket Blackfoot/Frog/Clod Buster motor mount. This allows the use of a 15T pinion with the DT-01 gearbox. For the motor & speed controller, I went to a 2500 kV, 16 turns brushless combo from Carson Modelsport. This allows long runtimes (more than 30 minutes on one 5000 mAh LiPo battery) and a quite fast top speed (slightly more than 40 km/h). You can find a video and more specs of my Mad Bull in the link of my signature below. Runner:

Sand Viper

,

Mad Bull

,

BMW Z4 Hatsune Miku

,

Kyosho Sandmaster EZ

Project: Hot Shot, Holiday Buggy 2010 (narrowed), Monster Beetle, Super Fighter G, MINI Cooper S 2006 Retired: The Hornet Still NIB: King Blackfoot

The following user(s) Liked this: PaulG

|

|

|

Please Log in to join the conversation.

Last edit: by GregM.

|

Time to create page: 0.184 seconds