TOPIC:

Richard's 4x4 Lunchbox with DF01 drivetrain. 3 years 8 months ago #67369

|

I post text and after edit the message and add the picts to avoid to lose all.

The following user(s) Liked this: jord001

|

|

Please Log in to join the conversation. |

Richard's 4x4 Lunchbox with DF01 drivetrain. 3 years 8 months ago #67401

|

My order of my bearings sadly got mixed up with other packages, so there will be a delay of my package.

But the shop rang me as soon as they got aware of the problem. My package is allready on the way to me. I need to post the package I received tomorrow. The shop owner was very sorry for the mess, but he was great to speak to. We need to give credit when it's due when someone do great service, usually we only hear the bad things. I will not hessitate to order from them again in the future. |

|

|

Please Log in to join the conversation. |

Richard's 4x4 Lunchbox with DF01 drivetrain. 3 years 8 months ago #67429

|

My bearings came in the post today.

I thought the 850 bearrings came in pack of 5, but I must have hastely read the description and assumed the 5x was the amount.. Well, well. Luckly I had a couple of those in my parts bin.

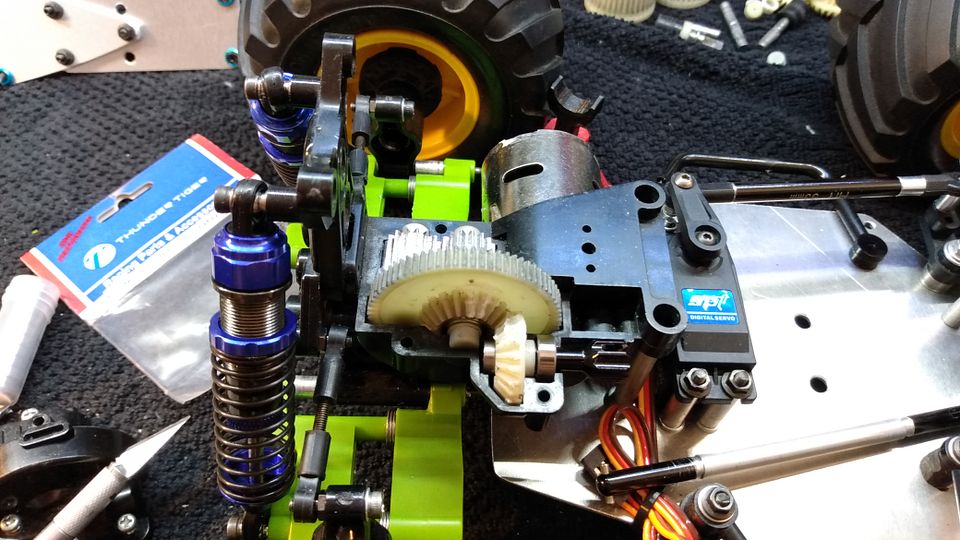

First I mounted the upper gears in the rear gearbox.

Next was the rear diff. I skipped installing my Manta Ray balldiff, and just used the normal gear one as the big tires might be a bit too big for the balldiff to cope.

Did the same for the front gearbox and all gears are greased as well so hopefully I don't need to open it up for a while. Propeller shaft is about 3mm too long to fit so it need to taken apart. The e-clips pushed the shaft a tad more out of the gearbox so it less space for the propeller shaft length. Only missing now from the running gear to make it complete is to fit pinion and to fit driveshafts. I do not have the correct length ones, but I do have these 6x83mm ones I can modify. The ball is perfect for the Tamiya drive cup since these has 6mm ball. Problem the pins on the driveshaft is slightly too big to go into the drive cup. So I either need to sand the pins down, or make the slot in the drive cups a tad bigger. The latter one may make the driveshafts to wobble if I don't make the slot equal. I think I will try to make the slot bigger with a 2mm cutting disc on angle grinder.

Slowly but surely this is getting closer to be done. I think I need to buy a new camera as the pictures really suck as they never seem to be sharp enough, kind of bluring especially on white things. Pictures are taken with my phone. I might test with my previous photocamera. |

|

|

Please Log in to join the conversation. |

Richard's 4x4 Lunchbox with DF01 drivetrain. 1 month 1 week ago #80134

|

The last few days I have been working on this project.

No pics as my bench is a mess. Since last time I worked on ths I now own a Wild Willy 2. Tested the rear wheel set and sadly the won't work on this as track ended up way too narrow (26.5cm) So I will use regular Lunchbox wheels as per now. I do need to order short M4 barrel as there is not enough thread on the TL01 wheelaxles.

The following user(s) Liked this: stingray-63, 1972 LeMansGT Jim

|

|

|

Please Log in to join the conversation. |

Richard's 4x4 Lunchbox with DF01 drivetrain. 1 month 1 week ago #80148

|

Some pictures for you all..

I managed to build a pair of 63mm front CVA shocks for my parts bin. New o-rings was added, rubber diagraph was fine. Fitted longer rod ends and some unknown green springs which are a tad too stiff. Had to space down top mount using two 1150 bushings. Everything is tight here. Wanted the camber link to be straighter, but due the propeller shaft cover is in the way, this is not possible. I might fit bent rod ends later. Found these. No idea what the are for, pin is in TL01 location but the rest of shaft is way longer than TG10 wheel axles as example. These was perfect to fit Lunchbox wheels and Lunchbox wheel adapter. Also perfect for the front wheels as well.. New wheel axles fitted Closer to be drive ready.. Due the long rear shocks there is more wheel travel then there is space for... 5-7mm space limiter should solve that out.. Rear springs a tad too soft so will try to find something better. Has loads of springs to pick from.. Need to: Shorten propeller shaft. Fit dog bones. Replace bearings in hubs. Find correct pinion. Swap motor. FInd better springs. Convert bearing front wheel to driv wheel (glue in a wheel bushing with slot for drive pin). Buy new tires (hese are borrowed from one of my MP's). Bodywork (ughh!!) |

|

|

Please Log in to join the conversation.

Last edit: by caprinut.

|

Richard's 4x4 Lunchbox with DF01 drivetrain. 1 month 5 days ago #80162

|

Ordered new tires and bearings today.

When they arrive my MP can get the current set back. Next is to convert the front bearing wheels to driven ones (make slot in metal bushings and then epoxy them to the wheels). Also need to make driveshafts (45mm drive shafts is out of stock here - WR02CB ) My propeller shaft also needs to be be pulled apart and reglued. I used green locktite (machine locktite) so I need some sort of heat. I only have heat gun and soldering iron to choose from. Plan clamp one end and put weights on the other then apply heat. Basicly my propeller shaft is 2-3mm too long currently so it binds when rotating. |

|

|

Please Log in to join the conversation. |

Richard's 4x4 Lunchbox with DF01 drivetrain. 1 month 1 day ago #80164

|

This ended up not working.

My soldering iron gets up to 400c, but I guess heat loss was too much. But approx 15min at 300c in the oven did the trick. Had to pull hard with pliers. This glue is no joke! After clean up. I ended up grinding off nearly 3mm of both sleeve and the small end. Now it fits with 1.5mm or so of slack. Perfect! Hard to spot, but you see the bronze colored end on the other side... Even harder to spot up front... I have yet reglued it. I wanted to make sure it would fit this time... I also made my drive conversion bushings today. Using the old serated busings as epoxy will have more surface to grab on. Epoxy`d them in.... Will clean the wheels before I put them on. Propeller shafts need reglueing. Chassis plate needs paint. Locktite all metal to metal screws. Fit new bearings to rear uprights. May need to trim the stock Lunchbox wheel adapters as they get tight when nuts are fully tighten. Make drive shafts. Bodywork. Add wheeliebar. |

|

|

Please Log in to join the conversation. |

Richard's 4x4 Lunchbox with DF01 drivetrain. 4 weeks 4 hours ago #80175

|

Fitted the new tires and bearings today.

While ordering I was tempted to order 45mm drive shafts, because this uses WR-02CB suspension arms which uses 45 drive shafts... Good I didn`t as I suspected mine was a bit different using DF01 gearboxes. Found some random 46.5mm drive shafts in my spar parts bin, but only two.. Tested up front and here it is about 4mm slack end to end. Due tight clearances, I will use these up front with 3 o-rings to make sure they stay in... In the rear it is about 5mm slack, so I should use 48-50mm drive shafts really. Problem they are out of stock anywhere here in Norway, or cost too much for what they are.. New tires fitted Found these 63.5mm drive shafts. If I don`t find anything else I will cut these and make 48mm drive shafts... 9803236 is really what I want, which is 48mm frond drive shafts for GF-01CB. And here a clip of my converted front wheels from bearings to pin driven, showing it works. |

|

|

Please Log in to join the conversation. |

Richard's 4x4 Lunchbox with DF01 drivetrain. 4 weeks 2 hours ago #80176

|

Awesome work on the rims Richard. And new lunchy tires are always exciting.

The following user(s) Liked this: caprinut

|

|

Please Log in to join the conversation. |

Time to create page: 0.149 seconds